Automated Facing and Centering Machine for Outer Race Machining

Highly Efficient Application of Facing and Centering Machines in the Machining of Outer Race for Constant Velocity Joints

In the modern automotive and precision machinery manufacturing industries, constant velocity (CV) joints serve as critical components within transmission systems, where their manufacturing precision and production efficiency directly impact overall vehicle performance and assembly quality. Among these components, the outer race is a key structural part of the CV joint. The accuracy, consistency, and processing efficiency of its end face machining and center hole drilling significantly influence the final product's quality. Traditional machining methods typically involve multiple processes, multiple machines, and manual loading/unloading, resulting in large space consumption, high labor costs, and difficulty in maintaining consistent machining precision. To address these industry challenges, automated facing and centering machines, with their highly integrated, automated, and rigid design, are emerging as exemplars of intelligent manufacturing in this field.

Core Functions and Application Scenarios of Automated Facing and Centering Machines

An"automated facing and centering machine"refers to a high-efficiency, high-precision CNC machining equipment that integrates milling, drilling, automatic loading/unloading, and workpiece inspection. Specifically designed for complex housing parts like the outer race of CV joints, its core functions include:

1. End Face Milling: Efficiently and smoothly machines the end face of the outer race, ensuring perpendicularity between the end face and the inner bore, as well as surface roughness, meet assembly requirements.

2. Center Hole Drilling:Precisely drills a center hole at the axial center of the outer race, providing an accurate positioning reference for subsequent processes such as turning and grinding.

3. Multi-Process Completion in a Single Setup: Utilizing precise tooling fixtures and CNC system control, the machine completes both end face milling and center hole drilling in a single clamping operation. This greatly reduces repetitive positioning errors and enhances machining accuracy.

This type of machine is widely used in automotive parts manufacturing, transmission system suppliers, and precision machinery workshops where high-volume production efficiency and consistent machining quality are paramount.

Analysis of Key Equipment Advantages

2.1 Compact Footprint

Traditional machining often requires multiple machines connected in series, occupying substantial floor space. In contrast, the automated facing and centering machine adopts a compact, integrated design, consolidating the milling spindle, drilling unit, automatic loading/unloading system, and chip removal apparatus within a single, compact frame. Its footprint is significantly smaller than traditional multi-machine setups, making it ideal for production lines with limited space or requiring dense automated layouts. This design not only reduces factory rental or construction costs but also optimizes material flow paths, enhancing overall production layout flexibility.

2.2 Excellent Chip Removal Performance

Milling and drilling processes generate significant amounts of chips. If not promptly and effectively removed, chips can scratch machined surfaces, affect workpiece quality, entangle cutting tools, clog guides, and even cause equipment failure. The facing and centering machine employs an **efficient chip removal system**, typically featuring high-flow coolant flushing, screw conveyors, or scraper-type chip conveyors, combined with an inclined worktable design. This ensures chips are rapidly and smoothly evacuated from the machining area. Effective chip removal prevents "secondary cutting," extends tool life, reduces maintenance frequency, and ensures long-term, stable, continuous operation.

2.3 Multi-Process Completion in a Single Setup

This is a core advantage of the automated facing and centering machine. Through precise composite fixtures and multi-axis control, the workpiece, once clamped in the fixture, can complete all designated processes. This completely eliminates cumulative errors introduced by repeated clamping, significantly improving positional accuracy (such as concentricity and perpendicularity) between the end face and the center hole. It also substantially shortens the machining cycle and reduces intermediate transfer time, achieving a dual leap in both "precision" and "efficiency."

2.4 Automation Integration

"Automation" is the essence of this equipment. Its design fully considers integration capabilities with upstream and downstream processes, allowing easy connection into automated production lines. Typical automation configurations include:

Loading Hopper: Stores raw or semi-finished workpieces and automatically feeds them into the machining area via mechanisms like vibratory bowls, robotic arms, or conveyor belts.

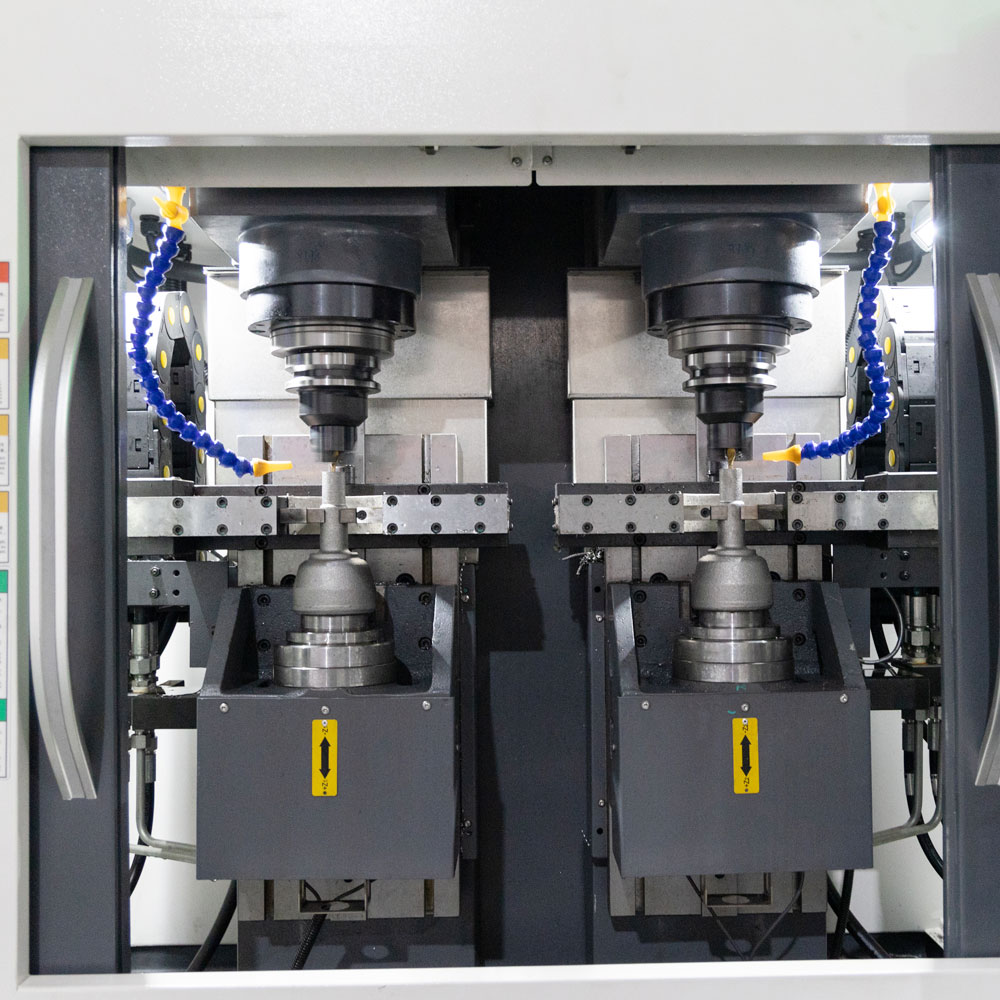

Dual-Station Machining: The machine features a dual-station design, enabling two workpieces to be processed simultaneously, significantly boosting production efficiency.

Workpiece Inspection Station: Some high-end configurations integrate online inspection functionality. After machining, the workpiece can be automatically transferred to the inspection station, where sensors or vision systems rapidly check critical dimensions (such as end face flatness, center hole depth/diameter), enabling closed-loop quality control and timely identification and rejection of defective parts.

Controlled by CNC systems, the entire process—loading, machining, inspection, and unloading—can run fully automatically, drastically reducing reliance on manual labor and improving production stability.

2.5 Frame-Type Rigid Machine Body

Machine rigidity is fundamental to ensuring machining accuracy and stability. This equipment utilizes a heavy-duty, frame-type welded steel structure that undergoes thorough stress-relief treatment. This design provides extremely high static and dynamic rigidity, effectively resisting vibration and deformation during cutting, ensuring stable machining accuracy and surface quality even during prolonged, high-intensity continuous operation.

Standalone Automation: A Flexible and Efficient Production Cell

Although the equipment possesses strong integration capabilities, it is also a highly sophisticated standalone automated production cell. For small and medium-sized enterprises that haven't established complete automated production lines, or for production modes involving multiple product types and small batches, a single automated facing and centering machine holds significant value.

In standalone mode, the operator simply loads a batch of workpieces into the loading hopper, starts the machine, and subsequent processes—machining, chip removal, finished part unloading (or temporary storage)—can be completed automatically. The operator only needs to intervene when the hopper is empty or full, enabling "one operator managing multiple machines" or "scheduled inspection" management models. This greatly enhances the output efficiency and labor utilization of a single machine. This flexibility allows the equipment to meet the automation demands of large-scale production while also adapting to flexible production scenarios involving multiple varieties and small batches.

Future Outlook and Industry Value

With the deepening development of Industry 4.0 and intelligent manufacturing, requirements for equipment automation, intelligence, and networking are increasing. This automated facing and centering machine not only meets the current demands for high efficiency and precision in outer race machining for CV joints, but its design philosophy—integration, automation, and high rigidity—also provides replicable solutions for machining other similar housing parts (such as bearing housings, gearbox casings, etc.).

Conclusion

In summary, this automated facing and centering machine, specifically designed for the outer race of CV joints, successfully addresses numerous pain points of traditional machining methods with its outstanding advantages: compact footprint, excellent chip removal, multi-process completion in a single setup, strong automation integration capability, and a frame-type rigid machine body, complemented by intelligent configurations such as dual-station design, loading hopper, and workpiece inspection station. It is not only a powerful tool for enhancing production efficiency and ensuring product quality but also a key piece of equipment driving the transformation of automotive parts manufacturing towards automation and intelligence. In today's pursuit of lean production and high-quality development, such automated facing and centering machines will undoubtedly become a crucial cornerstone for manufacturing enterprises to enhance their core competitiveness.