Heavy Duty Gear Milling Machine for Large Gears

Heavy-Duty Gear Milling Machine: The Giant of Gear Cutting

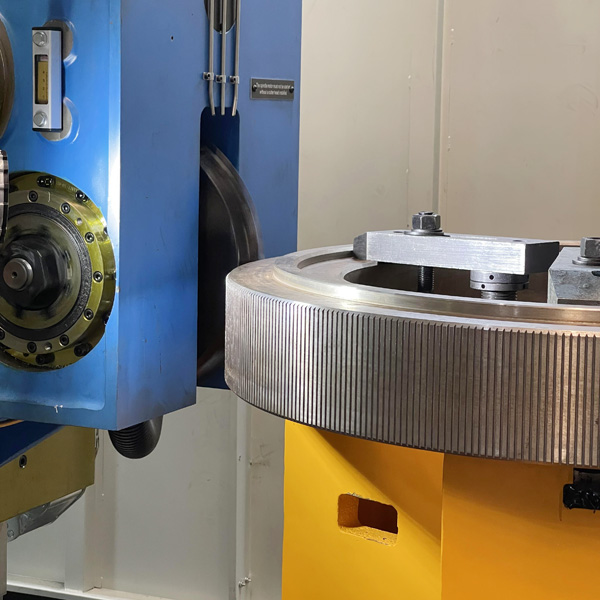

The first time I stood in front of a heavy-duty gear milling machine, I was honestly blown away. The machine is massive—tall, wide, and solid like a steel giant. What really shocked me was that it can handle gears up to 2 meters in diameter. It cuts both straight and helical gears, and the part I watched had 400 teeth. To finish one full circle takes about three hours. The cutting movement is slow and repetitive, but incredibly precise. Watching the cutter gradually shape one tooth after another felt oddly calming—almost therapeutic.

High-Efficiency Gear Cutting

The biggest advantage of a heavy-duty gear milling machine is speed and efficiency. With its high-performance carbide cutter heads, the machine is 3 to 6 times faster than traditional gear shaping or hobbing. For large gears, especially in industries like wind power, mining, or heavy machinery, this is a game changer.

Not only does the gear milling machine save time, but it also delivers stable accuracy. Straight or helical, big or small, it keeps the quality consistent while reducing errors that usually come from switching between multiple processes. This means fewer production delays, less scrap, and lower costs overall.

Built for Rigidity and Stability

This gear milling machine is designed following international standards. It uses a moving column with a rotary table layout, which makes the structure more rigid during cutting. The milling spindle box has dual-side drive and backlash elimination, keeping everything stable even under heavy loads.

The entire structure is optimized with finite element analysis. The column has a double-wall rib design, and the bed uses a "rolling + sliding"guide system. That mix gives both smooth motion and strong vibration resistance—perfect for large cutting forces. On top of that, the machine comes with smart milling software that can handle equal or unequal tooth division, giving more flexibility in production.

Reliable Components You Can Trust

To make sure the gear milling machine runs reliably, all the critical parts come from world-class brands. It's equipped with a Siemens SINUMERIK 828D CNC system, Siemens AC servo motors, and SINAMICS S120 drives. The variable-frequency drive comes from LG, and the high-precision gearboxes are imported from Alpha. Bearings are from top brands like SKF, FAG, and NTN.

This setup ensures that the gear milling machine performs with accuracy and stability, even during heavy-duty, long-hour machining. With this kind of quality, downtime is minimized, and production runs more smoothly.

Control System and Easy Operation

The machine uses a semi-closed loop control. The main movement is the tool spindle rotation, with the X-axis for horizontal feed, Z-axis for vertical feed, A-axis for tool angle adjustment, and C-axis for table rotation. The system combines CNC with a built-in PLC, making it fully digital. Feedback comes from pulse encoders inside the motors, which is reliable and cost-effective.

It also comes with a Siemens handheld controller, so operators can adjust parameters easily while standing right next to the gear milling machine. For companies that often work on custom gear designs, this user-friendly control system reduces setup time and makes training operators much easier.

Variable Speed and Safety

The spindle is powered by a 45kW variable-frequency motor, supporting stepless speed adjustment. Operators can adjust the spindle speed manually with a dial or let the program control it automatically. The motor system includes overload and overcurrent protection, making the gear milling machine safer and more stable during heavy-duty cutting.

Safety is critical when dealing with large gears and powerful cutters. The built-in protections allow operators to focus on productivity without worrying about sudden machine failures.

Hydraulic and Lubrication System

For stability, the machine uses a four-point hydraulic clamping system on the column. The guideways have distributed automatic lubrication, while the spindle box has a self-circulating oil system. Air cooling is used during cutting to keep the temperature under control and ensure clean, accurate tooth shapes.

These systems may sound like small details, but they make a big difference in real-world operation. A gear milling machine often runs for hours on a single gear, and proper lubrication and cooling are essential for consistent performance.

Supporting Features and Services

The gear milling machine is equipped with a hydrostatic rotary table and a large twin-worm gear drive, giving it extra rigidity during high-speed cutting. It also comes with chip conveyors and semi-enclosed guards for protection. The X and Z axes have full covers to keep the guideways clean and extend service life.

On top of the hardware, the manufacturer provides complete process support—from designing cutter heads and fixtures to optimizing cutting parameters. This means customers don't just get a machine, they also get expert know-how. That support is especially valuable for companies entering new markets or upgrading their production lines.

Applications Across Industries

The heavy-duty gear milling machine plays a key role in several industries. In wind power, large gears are needed for turbines, and the machine's ability to handle big modules makes it perfect for the job. In mining, heavy-duty equipment relies on massive gears for durability and power transmission. In shipbuilding, wide gears with high torque requirements benefit from the machine's precision. Even engineering machinery such as excavators and cranes use gears cut by this kind of equipment.

Every industry values reliability, and the gear milling machine delivers just that—faster, stronger, and more precise production.

Comparing with Traditional Methods

Compared to gear shaping or hobbing, the gear milling machine stands out. Gear shaping is versatile but slow, especially for large modules. Hobbing is efficient for smaller gears but struggles with very large diameters. The gear milling machine combines the best of both worlds: it can handle massive gears while still maintaining excellent speed and precision.

This efficiency also reduces costs. A job that might take multiple shifts on traditional machines can often be done in a single shift on a heavy-duty gear milling machine. Over the course of a year, that translates into huge savings.

Key Specs

Max module: 26 mm

Cutter head diameter: 380–420 mm

Cutter shank diameter: 90 mm

Cutter thickness: 100 mm

Helix angle: ±22.5°

Max gear width: 650 mm

These numbers show that the gear milling machine can handle **large modules and wide gear teeth**, making it perfect for heavy-load, high-precision applications.

Future

As industries move toward automation and digitalization, the gear milling machine will only grow in importance. With CNC control, smart software, and advanced safety systems, it's not just a traditional machine—it's part of the future of intelligent manufacturing.

Companies that invest in this kind of equipment gain a competitive advantage. Faster production, lower costs, and reliable performance mean they can deliver high-quality gears to markets that demand nothing less.

Final Thoughts

The heavy-duty gear milling machine isn't just a big piece of equipment—it's a true workhorse in modern gear manufacturing. Every detail, from its structural design to the CNC system and safety features, reflects the pursuit of efficiency, precision, and reliability.

With its speed advantage—up to 6 times faster than traditional methods—the gear milling machine is already reshaping production in industries like wind power, engineering machinery, mining, and shipbuilding.

Standing beside this giant, watching it slowly carve out one tooth after another, you can feel the power of modern manufacturing. It's not just a machine; it's a symbol of industrial strength and craftsmanship. And for the future of gear production, the heavy-duty gear milling machine will definitely remain at the center of it all.