Reduction Gearbox Guide: Types, Uses and Selection

Reduction Gearbox Guide: Types, Uses & Selection

Reduction gearboxes play a critical role in modern industrial transmission systems. From automated production lines to heavy machinery and precision manufacturing equipment, almost every mechanical system relies on a reduction gearbox to control speed and increase torque.

Although gearboxes may appear simple from the outside, their internal gears require extremely high accuracy and durability. Even small errors in gear profile or surface finish can cause vibration, noise, overheating, or premature failure. For this reason, both gearbox design and gearbox manufacturing demand advanced engineering knowledge and precision machining technologies.

In this complete guide, we explain what a reduction gearbox is, how it works, the most common gearbox types, where they are used, and how modern gear cutting and grinding machines ensure reliable gearbox production.

What is a Reduction Gearbox?

A reduction gearbox, sometimes called a gear reducer or speed reducer, is a mechanical device that converts high speed, low torque input power into low speed, high torque output power.

This speed reduction is achieved through multiple sets of gears with different tooth counts. By changing the gear ratio, manufacturers can precisely control output speed and torque to match application requirements.

In industrial environments, reduction gearboxes are essential because electric motors typically operate at high speeds that are not suitable for direct use. Without a gearbox, machines would lack sufficient torque and could not perform heavy duty tasks safely or efficiently.

As a result, reduction gearboxes have become fundamental components in:

Gear manufacturing lines

CNC machine tools

Conveyor systems

Robotics and automation

Mining and heavy equipment

Automotive and driveline systems

Their reliability directly determines overall system performance.

How a Reduction Gearbox Works?

The working principle of a reduction gearbox is based on gear meshing and mechanical advantage.

Power enters the gearbox through the input shaft, which drives the first gear stage. Through a series of larger and smaller gears, rotational speed gradually decreases while torque increases proportionally. The final output shaft then delivers controlled power to the driven equipment.

Several factors influence gearbox performance:

Gear ratio

Gear accuracy

Tooth profile quality

Lubrication system

Housing rigidity

If gear geometry is inaccurate, efficiency decreases and wear increases rapidly. Therefore, precision gear cutting and finishing processes are extremely important during manufacturing.

This is why modern gearbox factories invest heavily in CNC gear hobbing machines and gear grinding machines to maintain consistent tooth geometry.

G150 G200 G350 G400 G500 G800 CNC Gear Hobbing Machine

profile / worm wheel Gear Grinding Machine

Main Types of Reduction Gearboxes

Different working conditions require different gearbox structures. Choosing the correct type improves both efficiency and service life.

Helical Gearboxes

Helical gearboxes use angled teeth to provide smoother meshing and lower noise. They are widely used in continuous-duty industrial equipment and machine tools because of their high efficiency and stability.

Worm Gearboxes

Worm gearboxes offer large reduction ratios within a compact structure. They are suitable for applications requiring self locking capability or limited installation space, such as lifts and positioning devices.

Planetary Gearboxes

Planetary or epicyclic gearboxes distribute load across multiple gears, delivering extremely high torque density. They are often used in robotics, automation systems, and high-precision equipment.

Bevel Gearboxes

Bevel gearboxes change the direction of power transmission, typically at 90 degrees. They are common in conveyors and right-angle drive systems.

Each reduction gearbox type requires different gear manufacturing methods and machining accuracy levels.

Applications in Modern Industry

Reduction gearboxes are not limited to heavy industry. Today, they are found in nearly every sector.

For example:

Automated assembly lines rely on gearboxes for stable speed control

CNC machine tools use precision reducers for accurate positioning

Wind turbines use planetary gearboxes to multiply torque

Gear manufacturing plants use reducers to drive cutting machines

In many cases, a single production line may contain dozens of reduction gearboxes working simultaneously.

Because of this widespread usage, gearbox reliability has a direct impact on productivity and maintenance costs. High quality gears are therefore essential.

How Reduction Gearboxes Are Manufactured?

The performance of a reduction gearbox depends largely on gear quality. Manufacturing high-precision gears requires several specialized machining steps.

First, gear blanks are prepared through forging or casting. Next comes rough machining to shape the basic geometry. The most critical stage is gear cutting, where accurate tooth profiles are generated.

The most common gear cutting processes include:

Gear hobbing for external gears

Gear shaping for internal gears

Gear milling for prototypes

Heat treatment for hardness

Gear grinding for final finishing

Each step must be precisely controlled to ensure correct tooth form and smooth engagement.

Without advanced CNC gear cutting machines, it would be impossible to achieve the accuracy required for modern industrial gearboxes.

Machines Used in Gearbox Production

Today's gearbox manufacturers rely on complete gear manufacturing solutions rather than standalone machines.

Typical equipment includes:

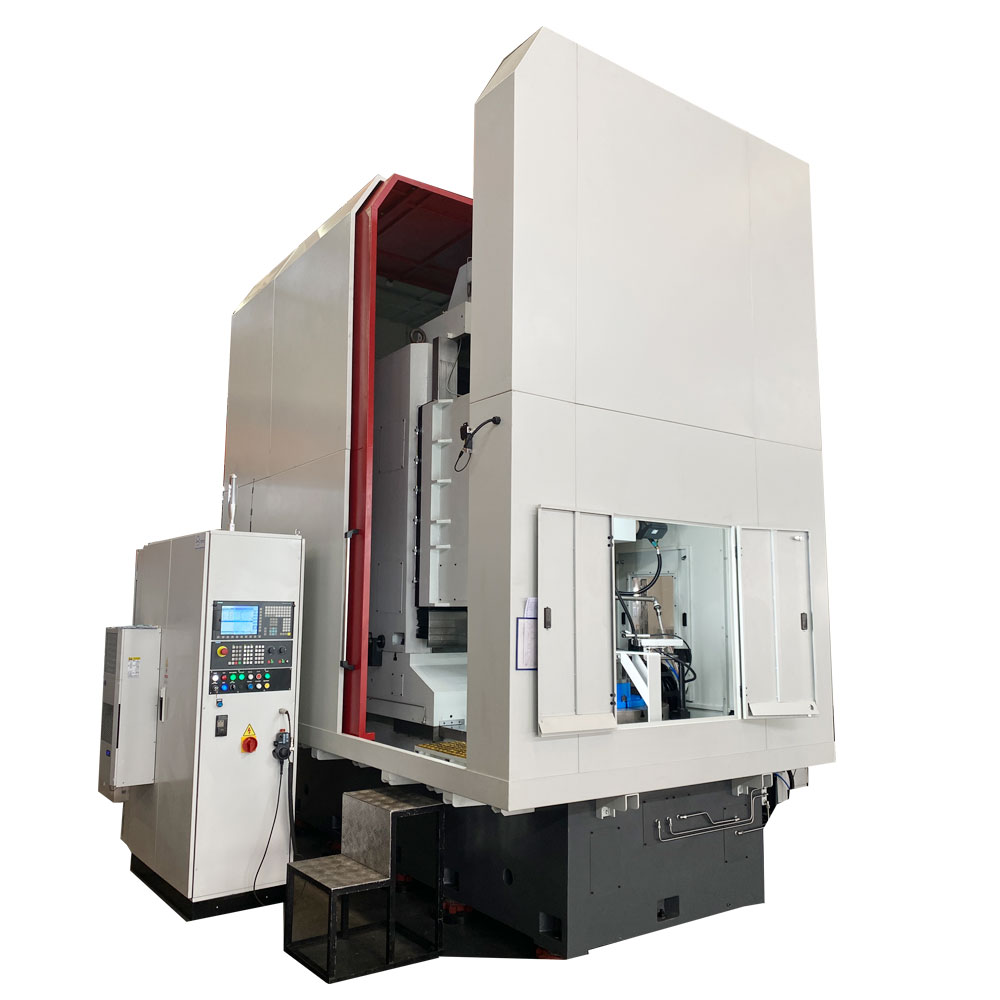

vertical / horizontal CNC Gear Hobbing Machine

Used for fast and accurate external gear cutting. Ideal for mass production.

G150 G200 YK3620 gear hobbing machine

GS200 GS400 Gear Shaping Machine

Essential for internal gears and ring gears.

Gear Grinding Machine

Ensures final precision and surface finish after heat treatment.

Automated Production Lines

Integrate multiple processes to reduce labor and increase consistency.

Gear Production Line / Automation Line

By combining these machines, factories can produce reduction gearboxes with high reliability and long service life.

How to Choose the Right Reduction Gearbox

When selecting a reduction gearbox, engineers should evaluate:

Required torque

Reduction ratio

Installation space

Duty cycle

Operating environment

Maintenance needs

In addition, it is often beneficial to work with suppliers who understand both gearbox design and gear manufacturing equipment. This ensures better compatibility between the gearbox and the machines driving it.

Future Trends in Gearbox Manufacturing

With the rise of Industry 4.0 and smart factories, gearbox manufacturing is becoming increasingly automated.

Trends include:

CNC digital control

Robotic loading systems

Online inspection

Integrated production lines

Energy efficient designs

Companies that adopt advanced gear cutting machines and automated systems can significantly improve productivity while reducing costs.

Conclusion

Reduction gearboxes remain essential components in modern mechanical systems. Understanding their working principles, types, and applications helps businesses make better purchasing and engineering decisions.

At the same time, high-quality gear manufacturing-supported by CNC gear hobbing, shaping, and grinding machines-is the key to producing reliable and long-lasting gearboxes.

For manufacturers looking to improve gearbox performance, investing in precision gear cutting equipment and automated production solutions is a long term strategy.