CNC Gear Hobbing Machine Shines at CIMT2025 exhibition

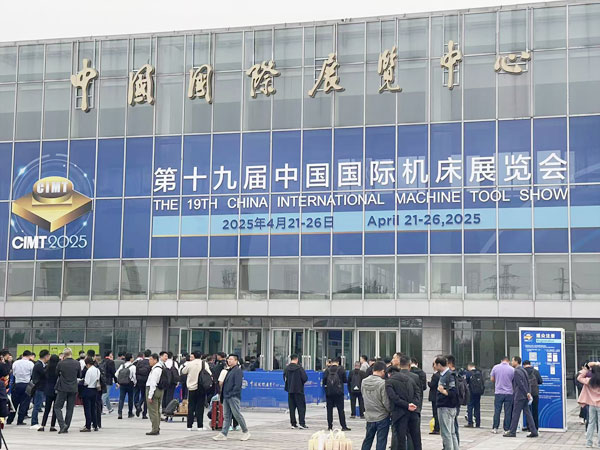

On April 26, CIMT2025, the China International Machine Tool Exhibition, concluded after a vibrant six-day event. The exhibition attracted over 2,400 participating companies from 31 countries and regions, showcasing products spanning the entire industrial chain, including precision machining centers, specialized machine tools, core components, cutting tools, and measurement instruments.

Highlight: The G200 High-Speed 6-Axis CNC Gear Hobbing Machine

At the exhibition, we showcased the G200 High-Speed 6-Axis CNC Gear Hobbing Machine, powered by a Siemens CNC operating system. Its intelligent interface simplifies the input of gear and tool parameters, while its advanced control system ensures precise task execution. Optional Weiming Tool Monitoring System integration enables fine control, real-time alerts, and analysis of tool conditions, actively safeguarding operations and enhancing safety and reliability.

Key Processing Capabilities

1. Maximum module: 6

2. Maximum workpiece diameter: 280 mm

3. Hob dimensions (max. installation): 180 mm (diameter) × 200 mm (length)

4. Axial travel distance: 200 mm

5. Maximum workpiece length: 670 mm

6. Effective spur gear tooth length: 300 mm

7. A-axis adjustment: ±45° for helical gears with large spiral angles

8. B-axis: Direct-drive motor provides high-speed rotation and cutting force, with hydraulic tool clamping for rapid tool changes.

9. Y-axis: Servo motor with precision gear drive ensures axial accuracy, extending tool life.

10. C-axis: High-torque direct-drive motor guarantees both indexing accuracy and robust cutting power.

This 6-axis machine excels in batch production, delivering efficiency several times higher than traditional mechanical models. The A-axis (helix angle adjustment) and Y-axis (automatic axial shifting) significantly reduce tool-changing and setup time for small-batch parts, creating greater value for gear manufacturers.

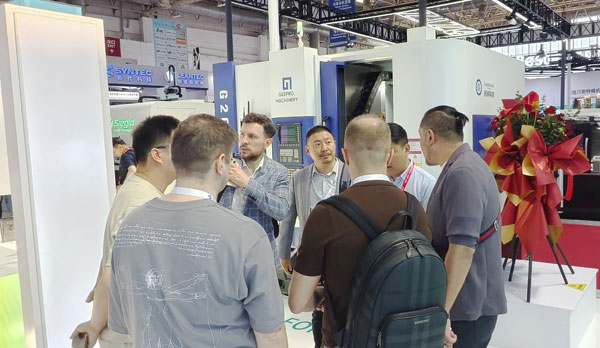

Engagement and Feedback

Our booth drew crowds eager to explore technical details and discuss customized solutions, aligning with customer needs for smarter production. Clients emphasized their demand for efficiency-boosting equipment, and the event provided invaluable market insights. We strengthened relationships with existing partners and forged new opportunities.

Moving Forward

CIMT2025 affirmed the capabilities of our gear hobbing machines while charting a path for future innovation. We remain committed to elevating product quality and service to meet evolving market demands. Looking ahead, we anticipate reuniting with industry peers at future global events to celebrate further technological breakthroughs and advancements.