Part 2:Gearbox Basics-Essential Knowledge for Beginners

For newcomers joining a gearbox manufacturing plant, understanding the structure and working principles of gearboxes is a crucial step in building a solid technical foundation. Gearboxes are widely used in industrial transmissions, automation equipment, construction machinery, new energy vehicles, robotics, and many other fields. Different types of gearboxes have distinct structural designs and applications. Understanding their core differences and internal components will help you adapt to the job more quickly and improve your skills effectively.

Ⅰ. Basic Concept of Gearboxes

A gearbox, also known as a reducer or transmission, is a mechanical device used to reduce rotational speed and increase torque. By utilizing various gear combinations, it transmits input shaft speed and torque to the output shaft in a controlled manner. Gearboxes are essential components in mechanical transmission systems and are commonly found in industrial machinery, wind power equipment, robots, electric vehicles, and agricultural machines.

Ⅱ. Common Types of Gearboxes and Their Principles

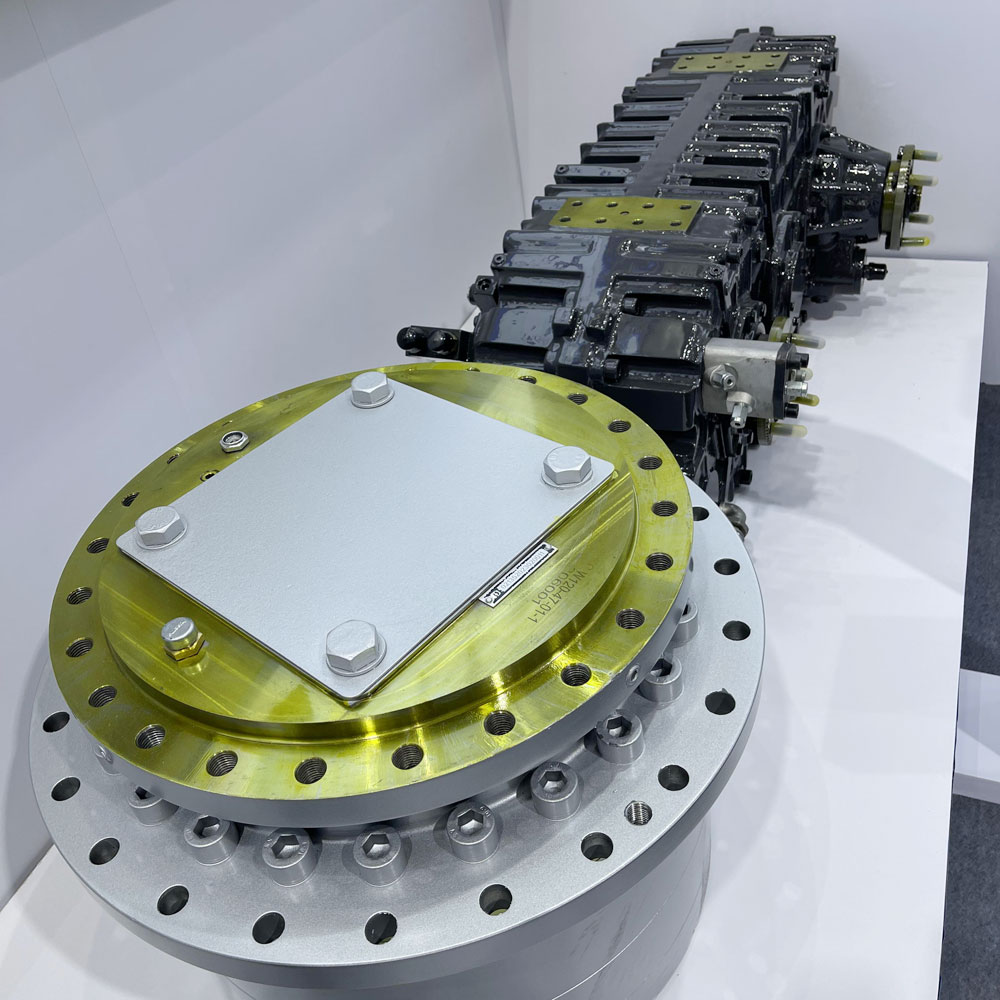

i. Planetary Gearbox

One of the most widely used structures, known for its compact size, high gear ratio, and strong load capacity. It consists of a sun gear, planet gears, planet carrier, and internal ring gear. The planet gears orbit the sun gear while rotating on their own axes.

Advantages:

Coaxial input and output

Multiple gear teeth in contact, high load-bearing capacity

Compact design, ideal for space-limited applications

Common in robotics, automation equipment, and electric vehicles

ii. Balancer Gearbox

Primarily used to eliminate unbalanced vibrations during mechanical operation, often found in internal combustion engines or dual-crankshaft systems.

Features:

Utilizes reverse-rotating gears for balancing

Reduces mechanical resonance and improves system stability

Common in automotive engines and high-speed machinery

iii. Bevel Gearbox

Designed for right-angle transmission, typically used to redirect power flow by 90 degrees.

Structure:

Uses bevel gears (straight or spiral)

Input and output shafts are usually perpendicular

Applications: Construction machinery, conveyor systems, packaging equipment

iv. Right Angle Gearbox

Also used for spatial right-angle transmission but not limited to bevel gears. It may adopt bevel gears, worm gears, or other mechanisms.

Differences:

Does not necessarily use bevel gears

Suitable for various right-angle transmission scenarios

Ⅲ. Main Structural Components of a Gearbox

Regardless of the type, most gearboxes consist of the following components:

i. Gear Sets

Spur gears: Simple, easy to manufacture, high efficiency, suitable for low-speed heavy-duty use

Helical gears: Smoother meshing and better load capacity, used in medium to high-speed applications

Bevel gears: Used for intersecting axis transmission

Planetary gear sets: Include sun gear, planet gears, and ring gear, ideal for compact, high-ratio applications

ii. Shaft Components

Input, output, and intermediate shafts serve as the medium for power transmission

Require high precision and heat treatment for durability

iii. Bearings

Support the rotating shafts and gears while reducing friction

Usually use rolling or sliding bearings

iv. Housing

The external casing that supports and aligns internal components while sealing lubricants

Common materials: cast iron, aluminum alloy, or welded steel

v. Sealing System

Prevents oil leakage and contamination ingress

Common elements: oil seals, O-rings

vi. Lubrication System

Provides lubrication to gears and bearings

Methods: splash lubrication, oil pump lubrication, oil mist lubrication, etc.

Ⅳ. Fundamental Knowledge System for Gearbox Beginners

To build a systematic understanding, new employees should focus on the following areas:

i. Gear Fundamentals

Gear meshing principles, module, number of teeth, pressure angle, etc.

Gear machining methods (hobbing, shaping, shaving, grinding)

Gear materials and heat treatments (quenching and tempering, carburizing, nitriding)

ii. Transmission Principles

Speed ratio calculations

Relationship between torque, power, and speed

Multi-stage transmission design and optimization

iii. Blueprint Reading

Ability to read part and assembly drawings

Understand dimensional and geometric tolerances (e.g., concentricity, parallelism)

iv. Processing and Assembly Procedures

Machining sequences of gearbox components

Assembly techniques: gear mounting, positioning, backlash adjustment

Precision inspection: runout, backlash, contact pattern

v. Fault Diagnosis and Maintenance

Common issues: noise, oil leakage, overheating

Routine maintenance: oil changes, seal inspections, bolt tightening, etc.

Ⅴ. Understanding Practical Applications

To enhance comprehension, it’s helpful to learn about how gearboxes are used across various industries:

Automotive transmission systems: automatic transmissions, differentials

Wind turbines: main gearboxes are typically planetary types

Industrial robots: use compact, high-precision planetary gearboxes

Food and packaging machinery: require clean, efficient, and low-noise transmission

Construction machinery: rotation drives in cranes, excavators, etc.

Ⅵ. Learning Tips

Start with assembly work: Learn component functions and how parts fit together on the shop floor

Learn from experienced technicians: Their practical troubleshooting and process knowledge is invaluable

Compare drawings and real parts: Strengthen 2D-to-3D understanding

Familiarize yourself with product lines: Understand different models, structures, and customer applications

Conclusion

As a newcomer to the gearbox industry, mastering the types, structures, components, and principles of gearboxes is your first step toward becoming a technical expert. Begin with the most common planetary gearboxes, study real products and drawings, then expand your knowledge to other types such as bevel gearboxes, balancer gearboxes, and right-angle gearboxes. Only by combining theory with practice can you truly understand the core of mechanical transmission technology.

learn more: Understanding the Difference Between Gearbox and Reducer

Part 1:Gearbox Types and Structures Explained Clearly