Understanding the Difference Between Gearbox and Reducer

learn more:

Part 1:Gearbox Types and Structures Explained Clearly

Part 2:Gearbox Basics-Essential Knowledge for Beginners

Understanding the Difference Between Gearbox and Reducer: Structure, Applications, and Practical Examples

In mechanical transmission systems, gearboxes and reducers are two commonly used but often confused components. Many people have heard that 'a reducer is a type of gearbox with a speed reduction function,' but not all gearboxes are reducers. To clarify the relationship and distinctions between the two, this article explores the topic from the perspectives of definition, structure, application fields, and real-world examples.

I. Definition Differences

1. Gearbox

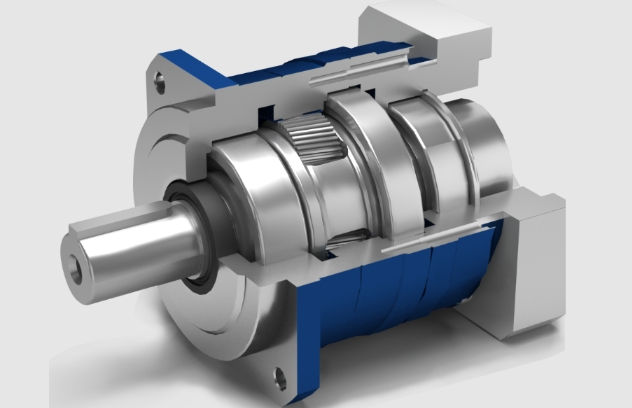

A gearbox is a mechanical transmission device primarily composed of gear pairs, shafts, bearings, and housing. Its core function is to alter the speed, direction, and torque between the input and output. Gearboxes can be used for speed reduction, speed increase, directional changes, and power distribution.

2. Reducer

A reducer is a specific type of gearbox whose primary purpose is to reduce speed—that is, to convert high-speed input from a motor or other power source into low-speed output, while simultaneously increasing torque. In other words, a reducer is a gearbox designed specifically for deceleration.

Therefore, all reducers fall under the category of gearboxes, but not all gearboxes are reducers.

II. Structural Components

Both devices share similar basic structural components:

Gear pairs: such as helical gears, spur gears, bevel gears, and planetary gears

Input and output shafts

Bearings and sealing systems

Housing and lubrication system

However, reducers tend to focus more on gear design for specific reduction ratios and torque capacity, often integrating directly with motors (e.g., with motor flange interfaces). In contrast, gearboxes are more versatile and can be used in applications requiring speed increase, power splitting, or complex shifting functions .

III. Application Field Comparison

1. Typical Applications of Reducers:

Industrial automation equipment (e.g., conveyors, packaging machines, robots)

Metallurgical equipment (e.g., rolling mills, crushers)

Wind turbines (main gear reducers)

Lifting equipment (e.g., electric hoists, winches)

Logistics and handling systems

2. Typical Applications of Gearboxes:

Automotive transmissions (for shifting gears)

Marine propulsion systems

Aerospace transmission systems

Military machinery

Electric motor test benches

Although reducers use gearbox structures, gearboxes serve a broader range of purposes. They can reduce or increase speed and adjust movement direction or torque.

IV. Case Study and Example

Imagine you have a motor rated at 1500 rpm, but your equipment only requires 300 rpm and higher torque. If you connect the motor directly to the equipment, the excessive speed and insufficient torque can lead to mechanical failure or energy inefficiency.

The solution is to install a reducer between the motor and the load, reducing the speed from 1500 rpm to 300 rpm-a 5:1 reduction ratio. This decreases output speed while significantly increasing torque based on the principle of power conservation. This is the most common function of a reducer: slowing down and increasing torque.

Alternatively, if you're an automotive engineer needing a transmission system that allows the vehicle to adapt to various speeds and terrains, you'll require a multi-speed gearbox. This allows both deceleration (e.g., for uphill driving) and acceleration (e.g., for highway cruising), with more complex and flexible functions than a typical reducer.

V. Functional and Purpose-Based Comparison Summary

Item | Reducer | Gearbox |

Main Function | Speed reduction and torque increase | Speed reduction, speed increase, direction and torque adjustment |

Structural Complexity | Relatively simple | May be more complex and multifunctional |

Application Scope | Industrial transmission, automation, machinery

| Automotive, aerospace, military, heavy equipment |

Motor Interface | Usually included (integrated design) | Optional depending on application |

Control Function | Fixed reduction ratio | Variable speed, shifting, clutch functions |

VI. Conclusion

In mechanical design and equipment selection, understanding the differences between reducers and gearboxes is essential. If your goal is to reduce speed and increase torque, a compact and cost-effective reducer is the ideal choice. But for more complex motion control-such as multi-speed shifting or multi-axis power transmission-a more versatile gearbox should be considered.

In summary, a reducer is a highly specialized and widely used member of the gearbox family. While they share structural similarities, they serve different purposes. Selecting the right transmission solution will enhance equipment efficiency, reduce energy consumption, and extend service life.