Automated Gear Rolling Machine for Outer Race Splines

Application of Automated Gear Rolling Machine in Outer Race Spline Processing

With the growing demand in modern manufacturing for high precision, high efficiency, and automated production, traditional manual or semi-automatic gear machining methods can no longer meet the requirements of large-scale and high-accuracy production. As an important piece of equipment for gear and spline processing, the gear rolling machine has demonstrated even greater value after automation upgrades. In particular, when applied to outer race spline machining, the automated gear rolling machine can achieve high precision, chipless forming, and significantly improve production efficiency while reducing labor costs and operational risks.

I. Automated Gear Rolling Machine

The automated gear rolling machine is a precision machining tool for gears, splines, and shaft parts. It enables single-stage or multi-stage cold forming without material removal, producing precise tooth profiles chiplessly. Its applications cover a wide range, including spur gears, helical gears, tapered gears, missing teeth, parallel splines, as well as worms, threads, sprockets, straight grooves, oil grooves, and more.

The equipment is typically a 13–36 inch horizontal standard reinforced servo or hydraulic gear rolling machine, featuring high rigidity, precision, and efficiency, while meeting environmental protection standards. To support automated production, it can be equipped with truss-type or articulated robots to realize automated production lines.

Core Technical Parameters

Max Module: Up to 1.5 module shaft parts

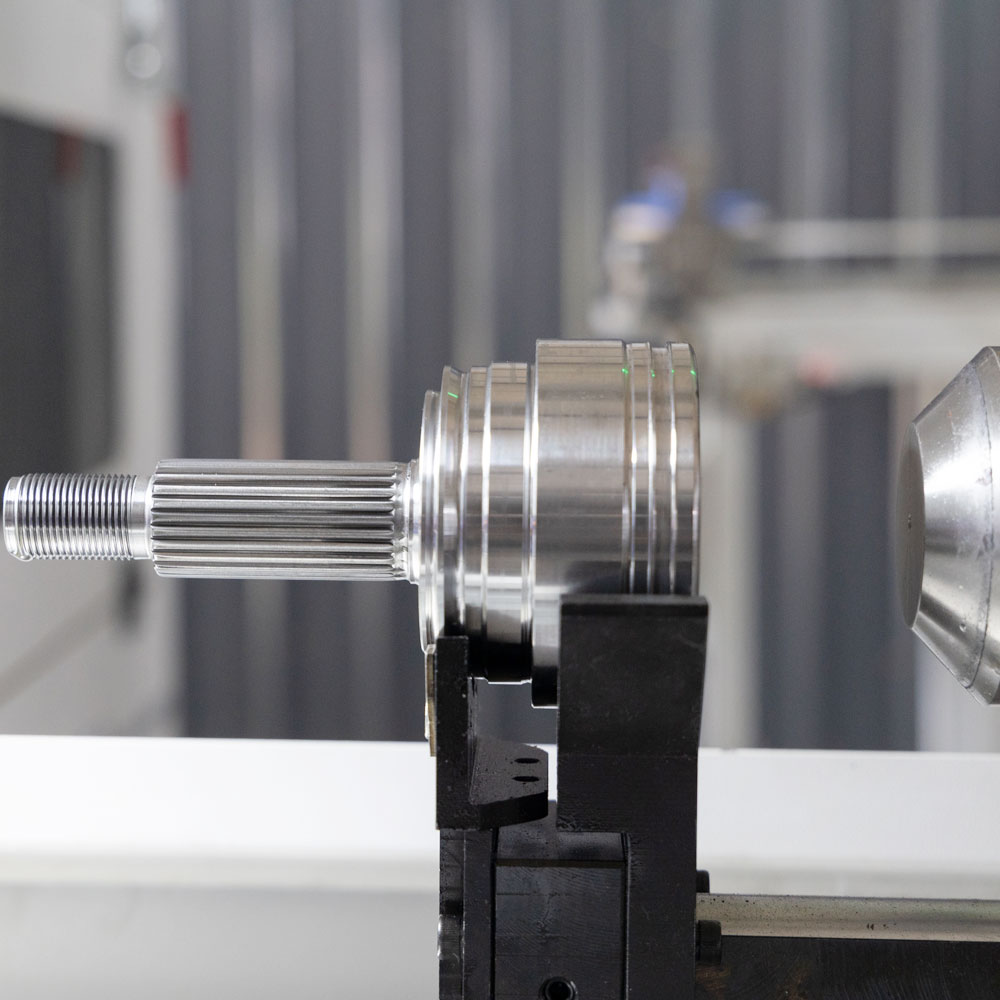

Workpiece Types: Outer race splines, spur gears, helical gears, tapered gears, and other special tooth forms

Drive System: Servo or hydraulic

Automation Configuration: Circulating magazine, loading/unloading rotary mechanism, automatic gripper, truss/articulated robots

Control System: High-precision CNC system for automatic parameter adjustment

II. Key Advantages of Automated Gear Rolling Machine

1. Improve Production Efficiency

The automated gear rolling machine achieves continuous machining of multiple workpieces without manual intervention through automatic loading/unloading, automatic material exchange, and a circulating magazine.

Continuous Operation: The magazine can load a large batch of workpieces at once. Combined with an automatic feeding system, the machine can operate stably for long periods.

Reduced Non-Machining Time**: Automatic loading and unloading shorten workpiece changeover time, maximizing machine utilization.

Ideal for Mass Production: Particularly suitable for large-scale, long-duration production tasks, reducing downtime and efficiency loss caused by manual intervention.

2. Ensure Machining Consistency and Quality

The automated gear rolling machine, through its CNC system and automated clamping devices, ensures precise control throughout the machining process:

Automatic control of clamping force, feed rate, and machining parameters, ensuring consistent results for each workpiece.

Automatic inspection functions monitor workpiece quality in real time, promptly identifying deviations and making corrections to ensure high-quality standards.

Chipless forming process reduces tooth surface damage and extends product lifespan.

3. Reduce Labor Costs and Enhance Safety

Automated operations significantly reduce manual intervention:

Lower labor demand, reducing workforce costs.

Higher operational safety, as automation minimizes direct worker contact with the machine.

24/7 continuous production capability, ideal for long-duration, high-volume tasks.

III. Application in Outer Race Spline Processing

Outer race splines are widely used in reducers, drive shafts, and various transmission systems. Due to their unique structure, they require high machining accuracy and surface quality. The automated gear rolling machine provides the following advantages in outer race spline processing:

1. High-Precision Spline Forming

Outer race splines often have large diameters and deep bores, requiring strict accuracy. The automated gear rolling machine, using servo/hydraulic drive systems and precision grippers, ensures stable clamping and prevents displacement during machining.

2. High-Efficiency Continuous Production

The automated magazine and truss robots ensure seamless and continuous processing of multiple outer race splines.

The automated unloading device transfers finished parts quickly to the next process or inspection area, improving overall production line efficiency.

3. Environmental Protection and Energy Saving

Chipless machining reduces waste and eliminates the need for chip disposal.

Efficient servo drives and optimized energy utilization lower overall power consumption.

4. Flexible Workpiece Adaptability

The automated gear rolling machine is not only suitable for standard outer race splines but can also handle various special tooth forms such as tapered splines, missing teeth, or oil grooves. With automatic program adjustment and quick fixture changeovers, it supports flexible production for different product specifications.

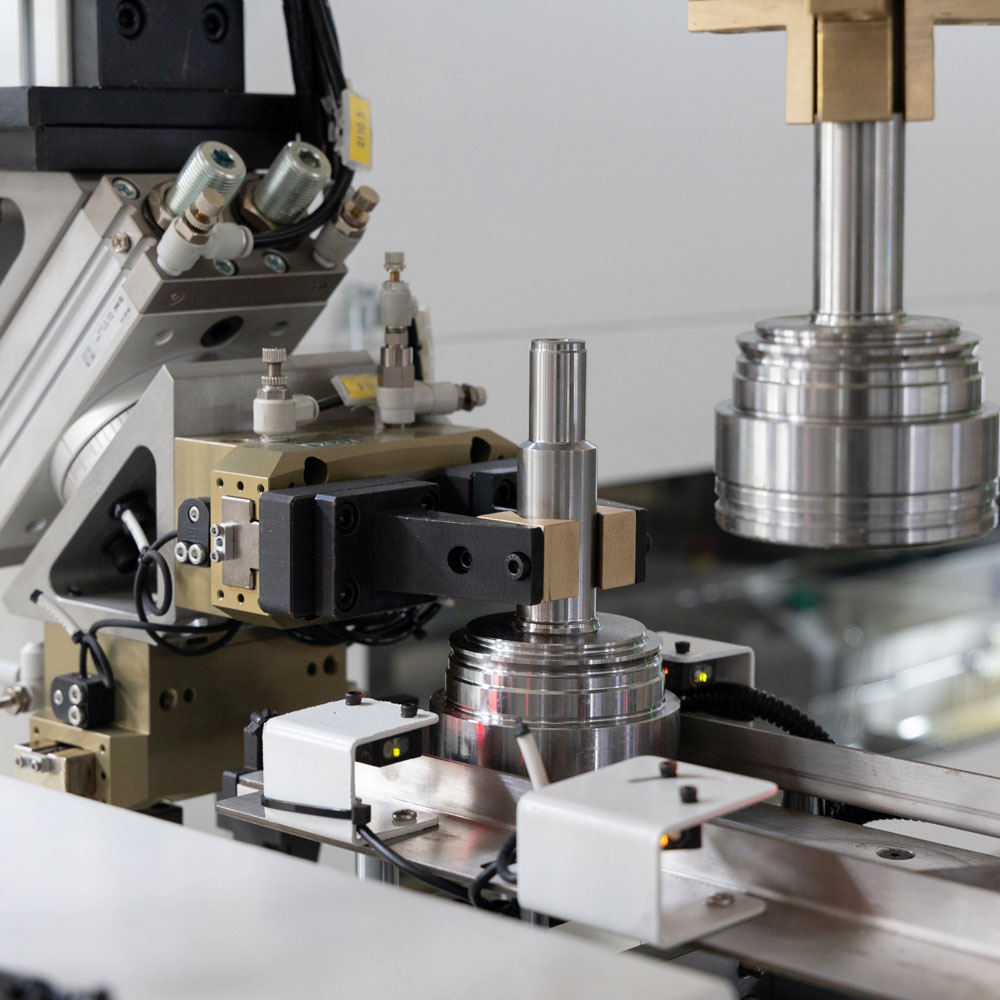

IV. Key Components of Automated Gear Rolling Machine

1. Loading/Unloading Rotary Mechanism

Automatically grips and transfers workpieces to the worktable for quick changeovers.

Works with the circulating magazine to enable long-duration, continuous supply with minimal manual intervention.

2. Automated Truss or Articulated Robots

Handle workpiece transport, positioning, loading, and unloading.

Enable 24/7 uninterrupted production, especially suitable for mass production scenarios.

3. Outer Clamping Jaw and Intelligent Clamping System

Driven pneumatically or electrically, providing rapid clamping and release.

Well-suited for high-speed automated production lines, improving cycle efficiency.

4. Automatic Inspection and Feedback System

Monitors workpiece quality in real time to ensure each outer race spline meets design requirements.

Provides automatic alarms and parameter adjustments when anomalies occur, ensuring stable production.

V. Application Cases and Production Value

In the manufacturing of automotive drive shafts, reducers, and construction machinery components, automated gear rolling machines are widely used for outer race spline processing. Production benefits include:

1. Batch Production Testing: In long-duration batch production tests, the equipment demonstrates excellent stability and accuracy.

2. Reduced Manual Operation: Operators only need to supervise and replenish materials, significantly reducing labor demand.

3. Improved Production Flexibility: Program adjustments enable quick changeovers between different workpiece specifications, meeting diverse production needs.

Overall, the automated gear rolling machine not only enhances production efficiency and machining precision but also reduces production costs and operational risks, making it an indispensable tool in modern manufacturing.

VI. Conclusion

The automated gear rolling machine demonstrates high precision, efficiency, low labor demand, and full automation in outer race spline machining. By integrating automatic feeding, clamping, truss/articulated robots, and intelligent inspection systems, it enables large-scale continuous production while ensuring product consistency and high quality.

For modern manufacturing enterprises, adopting automated gear rolling machines for outer race spline processing not only significantly boosts productivity but also guarantees product quality while reducing labor costs and operational risks—bringing both economic and technological value.