CNC Hob Sharpening Machine for Accurate Gear Cutting

Hob Sharpening Machine: A Key Guarantee in Gear Manufacturing

In the gear processing industry, the hob, as one of the core cutting tools, directly determines the quality and efficiency of gear production. However, as the service time extends, the cutting edge of the hob gradually wears out, leading to reduced cutting performance, and in severe cases, even affecting the gear's accuracy and surface quality. The hob sharpening machine is a specialized piece of equipment mainly used for the precise regrinding of hob flutes (tooth slots). This hob sharpening machine restores the sharpness and geometric accuracy of the cutting edge, ensuring that the hob continues to deliver efficient and stable cutting performance.

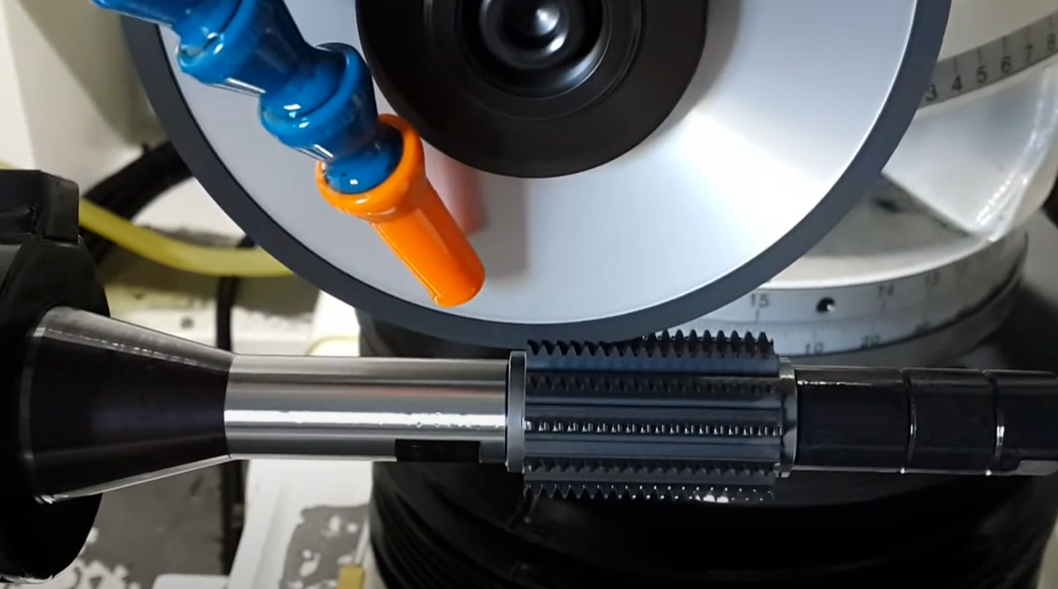

I. What is a Hob Sharpening Machine?

A hob sharpening machine is a specialized grinder designed for regrinding the flutes of hobs. The cutting edges of a hob are located on both sides of the flute, and long-term gear cutting will lead to wear of the cutting edges and increased cutting force. If not resharpened in time, not only will gear processing quality decline, but the hob itself may also be scrapped.

The core task of a hob sharpening machine is to use a high-precision grinding wheel to regrind the hob's flutes, restoring their original tooth profile angle, helix angle, and sharpness. With proper resharpening processes, hobs can be reused multiple times, significantly reducing the tool procurement costs of manufacturing enterprises.

II. Functions of a Hob Sharpening Machine

1. Restore Tool Performance

After resharpening with a hob sharpening machine, the hob regains its sharpness, ensuring gear processing quality and efficiency.

2. Extend Hob Life

A high-quality hob can usually be reground multiple times. Using a hob sharpening machine, the hob's service life can be extended severalfold, lowering tool costs.

3. Ensure Gear Machining Accuracy

High-precision hob resharpening effectively controls profile errors, ensuring consistency and accuracy of gear production.

4. Improve Production Efficiency

Using sharp hobs for gear cutting reduces cutting resistance and machining time, thereby improving overall production efficiency.

III. Main Structure and Working Principle

1. Bed and Worktable

Provide stable and rigid support, ensuring accuracy and stability during resharpening.

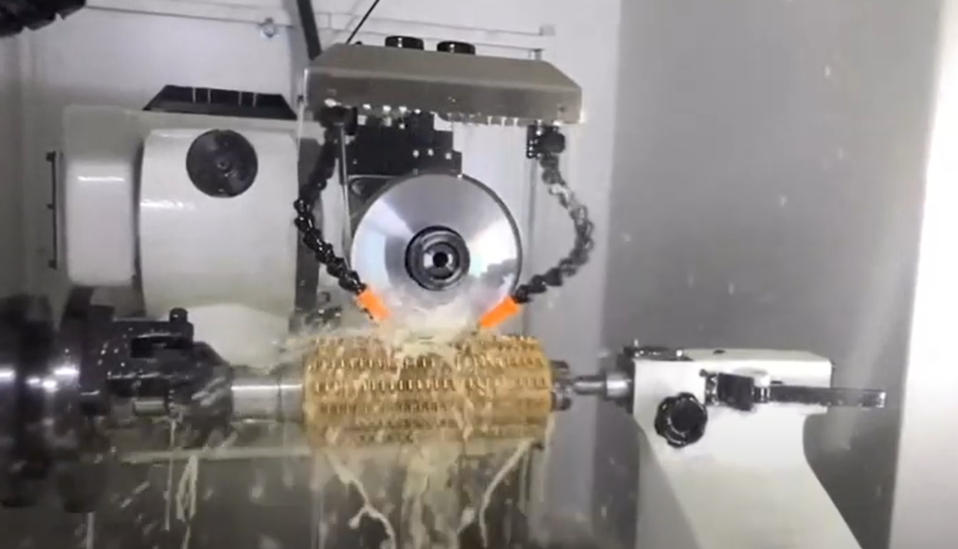

2. Grinding Wheel Spindle System

The high-speed rotating grinding wheel is the core component for resharpening. It must have excellent dynamic balance and rigidity to guarantee surface quality.

3. Hob Clamping and Rotating Device

The hob is fixed by fixtures and can be precisely indexed and rotated during grinding, allowing the wheel to align accurately with each flute for resharpening.

4. CNC System

Modern hob sharpening machines generally adopt CNC systems, which enable automatic indexing, angle compensation, and grinding path control, greatly improving precision and efficiency.

Working Principle: The grinding wheel follows a programmed trajectory along the hob flute surface, removing worn material and restoring the cutting geometry.

IV. Application Scope and Industries

Hob sharpening machines are widely used in gear manufacturing companies, hob producers, and tool resharpening service providers. They mainly serve industries such as:

Automotive Industry: For the production of transmission gears, differential gears, etc.

Construction Machinery: Suitable for gears in loaders, excavators, bulldozers, and other large equipment.

Wind Power: Wind turbine gearboxes require large-module, high-strength gears, creating significant demand for hob resharpening.

Shipbuilding and Aerospace: Require stable transmission and long service life, with extremely high precision requirements for hobs.

Mining Machinery and Metallurgical Equipment: Large-module gear production often requires multiple hob resharpening cycles.

V. Advantages of Hob Sharpening Machines

1. High Precision

Ensures that resharpened hobs are restored to their original design accuracy, guaranteeing gear quality.

2. Ease of Operation

Modern CNC hob sharpening machines support automatic indexing and programmed operation, reducing dependence on manual skill.

3. Strong Adaptability

Capable of resharpening hobs of different modules and types, meeting diverse gear processing needs.

4. Cost Reduction

Tools can be reused many times, saving significant procurement costs.

VI. Development Trends

With gear manufacturing advancing toward higher precision and efficiency, hob sharpening machines are showing the following trends:

1. CNC and Intelligent Control

Intelligent CNC systems enable automatic programming, on-machine inspection, and resharpening compensation, improving efficiency and consistency.

2. High-Precision Grinding Technology

Advanced grinding wheels and online measurement technologies ensure resharpening accuracy at the micron level.

3. Green Manufacturing

The use of oil-free cooling or minimum quantity lubrication (MQL) technologies reduces environmental impact and resource waste.

4. Digitalization and Networking

New-generation hob sharpening machines can be integrated into MES systems for production monitoring and traceability.

VII. Conclusion

As an important piece of equipment in the gear manufacturing supply chain, the hob sharpening machine takes on the role of "tool regeneration." It not only extends the service life of hobs and reduces tool costs but also ensures the accuracy and quality of gear machining. With the manufacturing industry moving toward high-end and intelligent production, hob sharpening machines will see broader applications, and their technical level will continue to improve, providing stronger support for the gear industry.

In the future, with the rapid development of high-end equipment manufacturing, hob sharpening machines will play an even greater role in industries such as automotive, wind power, shipbuilding, and construction machinery, becoming a key driving force for the gear industry's advancement toward high-quality development.