CNC Chamfering Machines for Gear Edge Precision Cutting

Encountering the Chamfering Machine: From Exhibition to Partnership

video: https://youtube.com/shorts/WdxdEJTs3X4?si=VhA_QW6I6J8h1HWc

In the early days, we were not familiar with chamfering machines. Although we had been deeply involved in the field of gear processing for many years, our understanding of this type of equipment--dedicated to gear end-face chamfering-remained only at a conceptual level. It wasn't until the machine tool exhibition held in Beijing that we truly entered the world of the chamfering machine.

On the day of the exhibition, machine tool manufacturers from all over the country gathered together, and the venue was filled with the rhythm and power of industry. As we walked through the exhibition area, a chamfering machine brand from zhejiang caught our attention. Their booth displayed two machine--one vertical and one horizonta--each performing live demonstrations of chamfering operations.

As the machines rotated at high speed, the gears gradually formed smooth and precise chamfer lines under the cutting tools. The booth was surrounded by visitors, and many domestic and international customers stopped to watch. Several foreign buyers even discussed drawings and requirements with the manufacturer on site.

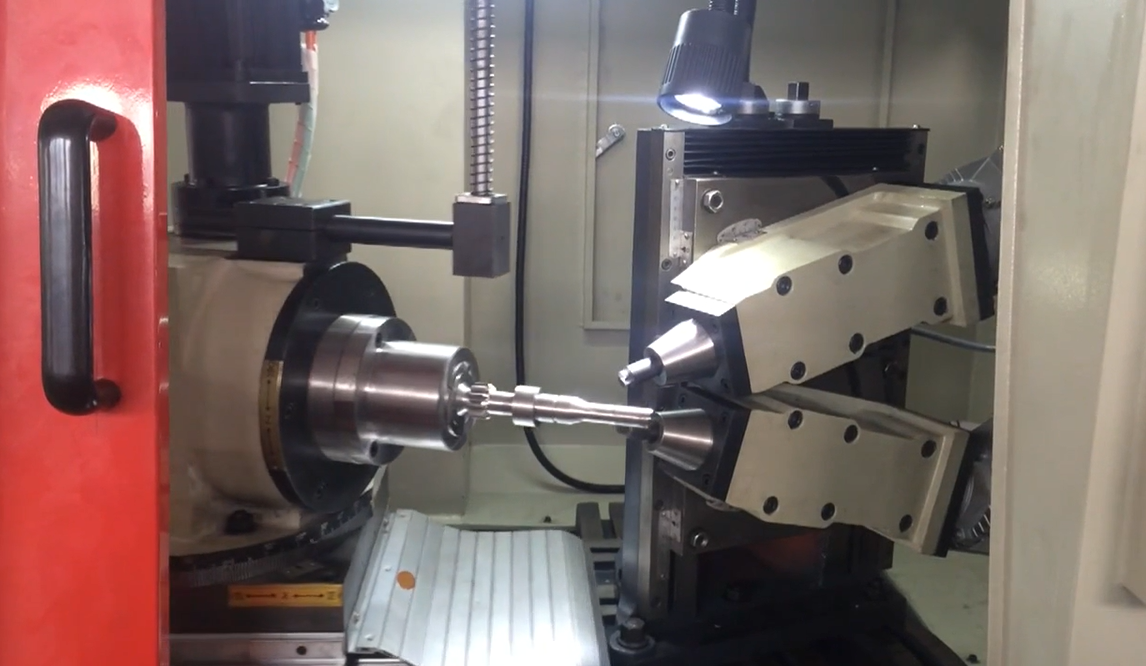

Upon closer inspection, I discovered that their vertical five axis CNC chamfering machine adopted an innovative structural layout. The upper and lower cutter spindles were arranged on the same side of a combined sliding table, forming a compact structure. Using a non-contact Balluff sensor, the system controlled the indexing to achieve the circumferential feed movement of the workpiece. Both the workpiece indexing and cutter feed movements were based on CNC interpolation principles. The workpiece spindle was driven by a servo motor, allowing adjustable rotation speeds. During continuous rotation, the high speed cutter spindle, under program control, performed uniform constant speed cutting along the gear profile to complete the chamfering process with high efficiency and stability.

Compared with traditional manual chamfering or cold extrusion and grinding methods, this CNC chamfering machine offered not only easier setup but also significantly higher consistency. The vertical design made workpiece loading and clamping more convenient. Its bed, column, and other critical components were made of high strength castings, stress-relieved through annealing and natural aging to ensure high rigidity and long-term structural stability. These design details revealed the company's strong technical foundation and commitment to product quality.

During further discussions, we learned that this CNC gear chamfering machine featured a modular design. The dual cutter spindles arranged on the same side enabled quick tool changes and easy alignment. On the opposite side, a hydraulic lifting tailstock was installed for shaft gear clamping, eliminating the need for an additional column. The structure was compact, the footprint small, and it was highly suitable for integration into automated production lines.

This type of chamfering machine not only delivered high machining efficiency but also greatly improved gear meshing quality. Through program control, both chamfer angle and size could be precisely adjusted, ensuring smooth transitions and consistent chamfer results. Gears processed with this machine generated less noise and exhibited better meshing performance, significantly enhancing overall gear quality and assembly accuracy. It is fair to say that this equipment established a new standard for chamfering in the gear manufacturing industry.

Moreover, the chamfering machine was designed with user friendly changeover functionality. It adopted a semi-split expansion sleeve structure that clamped the inner hole and positioned the workpiece based on the end face. Within a certain diameter range, only the expansion sleeve and locating ring needed to be replaced for product changeover. For larger variations, the tapered body, sleeve, and ring could be changed as a set. The entire product changeover process took only 10 to 20 minutes, while the first part setup for a new product required around 20 minutes. For subsequent production, the saved parameters could be directly recalled, enabling fast transitions between product types. Such a design greatly improved production flexibility and perfectly met the needs of modern multi-variety, small-batch manufacturing.

After watching the live demonstration and structural introduction, we had an in-depth technical discussion with the chamfering machine company's engineers. They explained the control system, tool compensation functions, and probe detection principles in detail, answering our questions about machining stability and gear specification adaptability. Their professionalism and confidence left a lasting impression.

After the exhibition, we held an internal evaluation meeting to discuss the possibility of cooperation with this zhejiang-based company. Following multiple rounds of assessment and technical comparison, we ultimately decided to introduce their chamfering machines into our operations. Soon after, both sides signed a cooperation agreement, establishing a strategic partnership.

In practice, this decision proved absolutely right. As our international business expanded, more and more foreign customers requested gear chamfering solutions. In the past, manual chamfering had been inefficient and inconsistent, but with CNC chamfering machines, both accuracy and efficiency improved significantly. Customers reported noticeable improvements in product quality and reductions in gear noise.

Over time, we successfully facilitated the export of five chamfering machines to overseas markets, including Southeast Asia, Russia, and Europe. After installation, customers gave highly positive feedback on the performance and machining precision of the machines. From that exhibition encounter to partnership and eventual global sales, we truly witnessed how chamfering machines transformed our capabilities.

Today, chamfering machines have become an indispensable part of our product portfolio. They not only enhance our processing capabilities but also allow us to offer more complete gear manufacturing solutions to our customers. From unfamiliarity to expertise, from observation to collaboration, and from domestic exhibitions to international market--our journey with chamfering machines reflects our continuous pursuit of technological innovation and progress.

Looking ahead, we will continue to work closely with our partners to advance gear manufacturing technology to higher standards, providing global customers with more efficient, precise, and reliable chamfering machine solutions.