Gear Cutting Methods Explained : Gear Hobbing to Grinding

Gear Cutting Methods Explained: Hobbing to Grinding

Gear cutting methods form the technical foundation of the entire gear manufacturing industry. Whether producing reduction gearboxes, automotive transmissions, wind power drives, or heavy equipment components, every gear must pass through a precise cutting and finishing process before it can operate reliably.

In modern factories, gear accuracy is no longer optional. Even micron-level errors in tooth profile or pitch spacing can lead to noise, vibration, excessive heat, and shortened service life. As performance standards continue to rise, manufacturers are moving away from traditional manual machining and adopting CNC gear cutting machines and automated production lines.

This article explains the major gear cutting methods-gear hobbing, shaping, milling, and grinding-and shows how these processes work together to build an efficient gear manufacturing system.

What Is Gear Cutting?

Gear cutting is the controlled removal of metal from a blank to create precise gear teeth with defined geometry. Unlike ordinary machining, gear cutting requires synchronized motion between the tool and the workpiece to generate the involute tooth profile.

The process determines:

Module accuracy

Tooth spacing

Profile error

Surface finish

Contact ratio

These parameters directly affect gearbox performance and durability.

Because of this complexity, most manufacturers rely on dedicated CNC gear machines rather than general-purpose equipment.

Why Gear Accuracy Is Critical?

Many engineers underestimate how sensitive gear systems are.

For example:

10-20 μm profile error → increased noise

Poor surface finish → faster wear

Inconsistent pitch → vibration

Incorrect backlash → overheating

In reduction gearboxes or precision drives, these issues can lead to early failure.

Therefore, modern gear manufacturing emphasizes not only cutting speed but also precision and stability. This is why advanced gear cutting machines and grinding machines are essential.

Method 1: Gear Hobbing (Core Production Process)

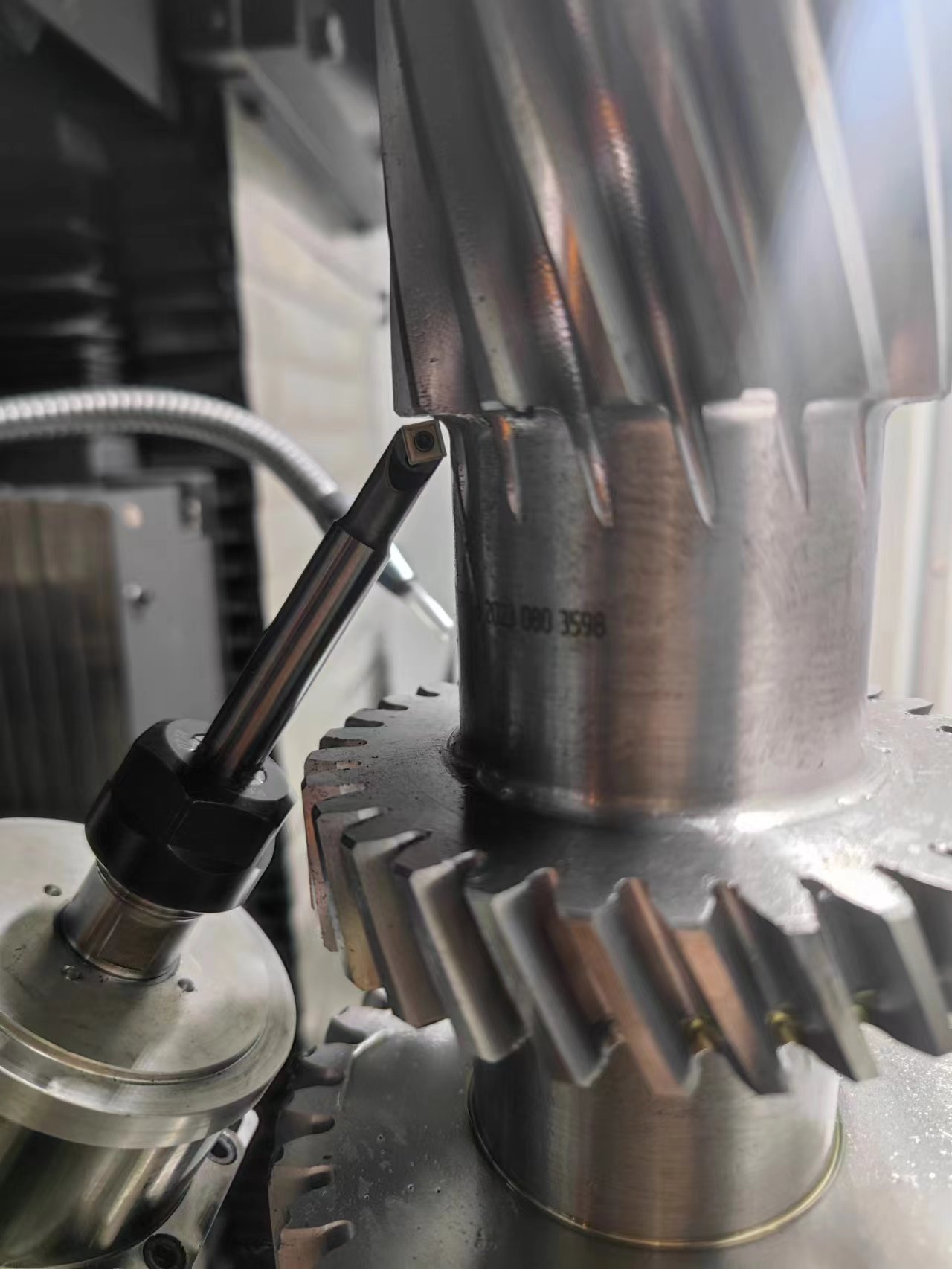

Principle of Gear Hobbing

Gear hobbing is the most widely used gear cutting method worldwide. A rotating hob cutter gradually generates the tooth profile while the workpiece rotates at a synchronized speed.

Unlike milling, which cuts one tooth at a time, hobbing is continuous. This makes it extremely efficient for large scale production.

Advantages of Gear Hobbing

High productivity

Continuous cutting motion

Excellent repeatability

Lower cost per part

Suitable for automation

For factories producing hundreds or thousands of gears daily, gear hobbing is usually the first choice.

CNC Gear Hobbing Machines in Practice

Modern CNC gear hobbing machines offer:

Multi-axis control (4-6 axis)

High-rigidity cast structure

Automatic tool change

Servo-driven spindles

Online measurement

Automatic loading systems

These features ensure both speed and accuracy.

G150 G350 G500 CNC Gear Hobbing Machine

Such machines are widely used in gearbox and transmission factories where consistent quality is critical.

Method 2: Gear Shaping (Internal Gear Specialist)

Gear shaping is particularly useful when cutting internal gears or gears close to shoulders where hobbing cannot reach.

A reciprocating cutter moves vertically while rotating with the workpiece, gradually shaping the tooth form.

When to Use Gear Shaping?

Ideal for:

Internal ring gears

Planetary carriers

Small-batch production

Complex geometries

Although slower than hobbing, shaping provides unmatched flexibility.

GS200 GS400 GS800 Gear Shaping Machine

Most gearbox manufacturers combine shaping and hobbing in the same production line.

Method 3: Gear Milling (Flexible and Prototyping)

Gear milling uses a form cutter to machine teeth individually.

While less efficient, it remains useful for:

Prototypes

Repairs

Small orders

Special tooth forms

CNC milling centers provide flexibility when dedicated gear machines are unnecessary.

Method 4: Gear Grinding (Precision Finishing)

After heat treatment, gears may warp slightly. Grinding corrects these distortions and achieves final accuracy.

Benefits of Grinding

Very high precision (DIN 5-6 or better)

Smooth surface finish

Reduced noise

Extended life

Grinding is essential in:

Automotive gears

High end reducers

Aerospace drives

Profile/ worm wheel Gear Grinding Machine

Without grinding, high-performance gearboxes cannot meet modern standards.

Integrating Methods into a Gear Production Line

In real manufacturing, gear cutting methods are rarely used alone.

A typical workflow:

Hobbing (rough cutting);

Grinding (finishing);

Inspection

This integrated approach improves both speed and quality.

Automated Gear Production Line

How to Choose the Right Gear Cutting Equipment?

When selecting gear machines, consider:

Production volume

Gear type

Required precision

Budget

Automation level

A balanced combination of CNC gear hobbing machines, shaping machines, and grinding machines usually provides the best results.

Conclusion

Different gear cutting methods serve different purposes. Understanding their strengths helps manufacturers design efficient production systems.

By combining advanced CNC gear machines with smart automation, modern factories can achieve both high output and precision-- the key to competitive gear manufacturing.